Is Your Fleet Safety Plan Enough?

Roadway risks are escalating — and so are the stakes for businesses relying on fleet vehicles. From 2013 to 2022, motor-vehicle deaths surged by 30%, with mileage-related fatalities up 13%, according to the National Safety Council (NSC).

For companies operating fleets, these trends underscore a non-negotiable truth: A proactive fleet safety program isn’t just about compliance — it’s a lifeline for protecting drivers, reducing costly incidents and safeguarding your bottom line. But what, exactly, is an effective fleet safety plan?

What Is Fleet Safety?

Fleet safety is a strategic, proactive approach to minimizing accidents, injuries and vehicle damage through systematic policies, driver training and equipment maintenance. It’s not just reactive measures — it’s about anticipating risks before they escalate.

With motor-vehicle crashes ranking as the costliest workers’ compensation claims (averaging $90,914 per claim from 2021–2022, per NSC), poor fleet safety doesn’t just endanger lives — it disrupts operations, inflates insurance costs and tarnishes reputations.

What Is a Fleet Safety Program?

A fleet safety program is your actionable blueprint for protecting drivers and assets. Over 4.35 million U.S. workers regularly drive for work, facing risks from distracted driving to mechanical failures. An effective program combines three pillars:

- Vehicle inspections: Pre-trip checks to catch issues like worn tires or faulty brakes.

- Driver safety training: Coaching on defensive driving and accident prevention.

- Preventative maintenance: Scheduled servicing aligned with manufacturer guidelines.

By addressing both driver behavior and vehicle condition, these programs reduce preventable incidents, keeping your team safe and your fleet productive.

Why Is Fleet Safety So Important?

Ignoring fleet safety is a gamble no business can afford. Beyond the human toll of collisions, the financial and operational impacts are staggering.

Preventive maintenance plans are essential for securing the long-term safety of your employees and keeping company vehicles running at peak condition. Having your drivers routinely inspect and monitor vehicle conditions allows you to identify minor (and major) issues before they mature into dangerous problems. And a consistent maintenance schedule can give you and your employees the peace of mind needed to get the job done without unnecessary risk.

Here’s how a robust fleet safety strategy protects your people and property:

- Accident reduction: The Occupational Safety and Health Administration (OSHA) ranks fleet maintenance and inspection among the most effective tools for reducing workplace vehicle accidents. Company vehicles that are well-maintained perform better in almost every situation, which is especially important when reacting to unexpected roadway hazards.

- Improved driver confidence: Vehicles in top condition are much easier to operate and control, in part because drivers trust they will perform reliably (and predictably) in difficult situations. Additionally, your employees will be more likely to drive safely and handle your fleet with care if each vehicle is routinely maintained.

- Reduced repair costs: Establishing fleet safety guidelines can help you save on overall maintenance costs, as scheduled repair work is typically three to four times more cost-effective than unplanned repairs. Vehicle repair schedules should always consider the specific mileage recommendations provided by the manufacturer and correspond to state and federal regulations.

- Increased vehicle productivity: Lengthy repairs can put vehicles out of commission for days, even weeks, which may seriously impact productivity for companies with smaller fleets. Preventative maintenance helps minimize interruptions to your workflow by reducing the frequency of breakdowns and major part replacements.

- Positive brand relations: Customers will appreciate your clean, well-maintained vehicles almost as much as your employees. By devoting time and energy to your fleet’s upkeep, you can demonstrate a commitment to professionalism and attention to detail that will reflect positively on your brand.

Developing an Effective Fleet Safety Program

A strong fleet safety program doesn’t happen by accident — it’s built through deliberate planning, consistent execution and a commitment to continuous improvement. Here’s how to design a program that protects your drivers, reduces liability and keeps your fleet running smoothly:

Drafting a Written Fleet Safety Policy

Start with a clear, enforceable policy that leaves no room for ambiguity. Outline expectations for driver behavior — including strict bans on distracted driving, adherence to speed limits and mandatory seat belt use.

Provide detailed protocols for pre-trip vehicle inspections, accident reporting and maintenance schedules. Be sure to align your policy with OSHA regulations and FMCSA standards to avoid penalties and ensure compliance.

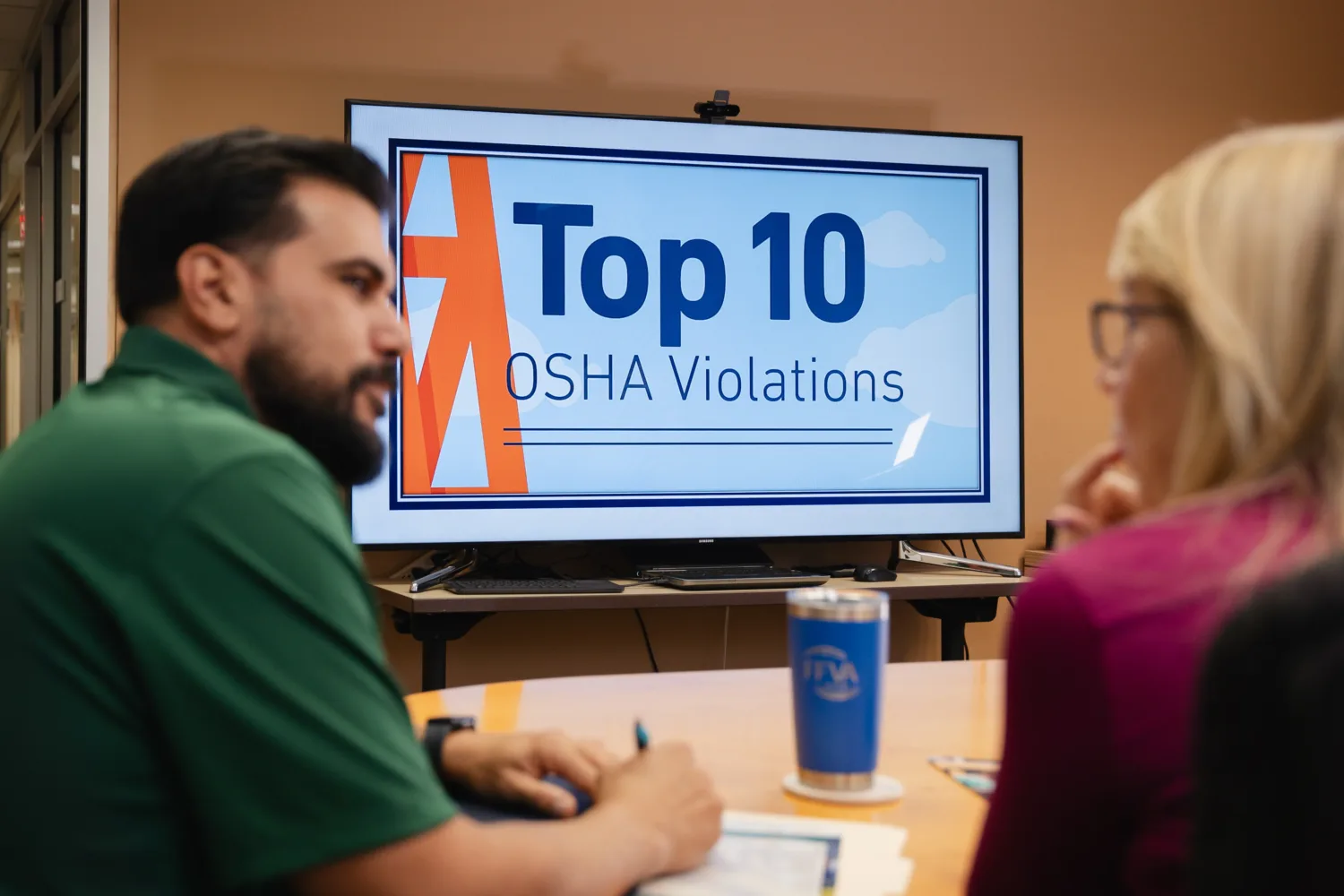

Implement Driver Safety Training

Even experienced drivers need refreshers. Launch initial and ongoing training programs covering defensive driving techniques, emergency response and fleet safety certification. Address high-risk behaviors like harsh braking, speeding and phone use behind the wheel. Gamify progress with rewards for safe drivers — think bonuses or public recognition — to incentivize participation.

Remember: Training isn’t a checkbox exercise; it’s an investment in reducing driver risk and fostering long-term safer driving habits.

Conduct Regular Vehicle Inspections

Catching a frayed brake line early can prevent a catastrophe. Mandate pre-trip and post-trip inspections using a standardized fleet safety checklist covering tires, lights, fluid levels and safety equipment.

Streamline the process with fleet management software to log issues, assign repairs and track maintenance histories. This dual focus on accountability and technology ensures minor flaws don’t snowball into major hazards.

Monitor Driver Behavior and Performance

Telematics and GPS tracking provide undeniable insights into driver performance. Use this data to identify unsafe behaviors — such as sudden acceleration, erratic lane changes or idling — and deliver real-time feedback.

Pair critiques with positive reinforcement: Recognize drivers who exemplify safe driving practices through low-risk scores or perfect inspection records. Over time, this transparency builds a culture where accountability is the norm, not the exception.

Schedule Preventive Maintenance

Breakdowns don’t just stall deliveries — they put drivers in danger. Create a preventive maintenance calendar tied to vehicle mileage and manufacturer guidelines.

Prioritize critical components: brake inspections every 12,000 miles, oil changes every 5,000 miles and electrical system checks quarterly. Partner with trusted mechanics to ensure fleet vehicles meet — or exceed — safety benchmarks.

Encourage a Safety-First Culture

Policies and tools only work if your team embraces them. Hold monthly safety meetings to review incident trends, celebrate safe drivers and discuss new risks like extreme weather or urban traffic patterns.

Empower employees to report safety concerns without fear of reprisal — and act swiftly on their feedback. Most importantly, fleet managers must model safe behavior: Buckle up, put phones away and prioritize caution over speed. When leadership walks the talk, safety becomes everyone’s responsibility.

How To Conduct a Fleet Vehicle Inspection

The best way to keep your drivers safe and secure is for them to inspect each vehicle before, during and after every trip, no matter how brief or routine the journey might be. Drivers should be encouraged to record the results of vehicle check-ups using a standardized vehicle inspection checklist. While it may sound excessive, a proactive approach to roadway safety requires close attention to even the minor details of your fleet’s condition.

Here are a few things your fleet safety checklist should include:

- Body damage

- Tire pressure and excessive wear

- Headlights, brake lights, tail lights and hazard lights

- Windshield and windows

- Turn signals

- Fuel levels

- Seat belts

- First Aid Kit

- Horn

Developing and using a standard vehicle checklist for all company vehicles and drivers is a great way to ensure the inspections are efficient and consistent. Remember, a strong fleet safety program starts with mutual understanding, so be sure to explain why these policies are important and how they benefit your employees in their day-to-day work.

For more information, download our vehicle inspection checklist and check out our instructional online resources.

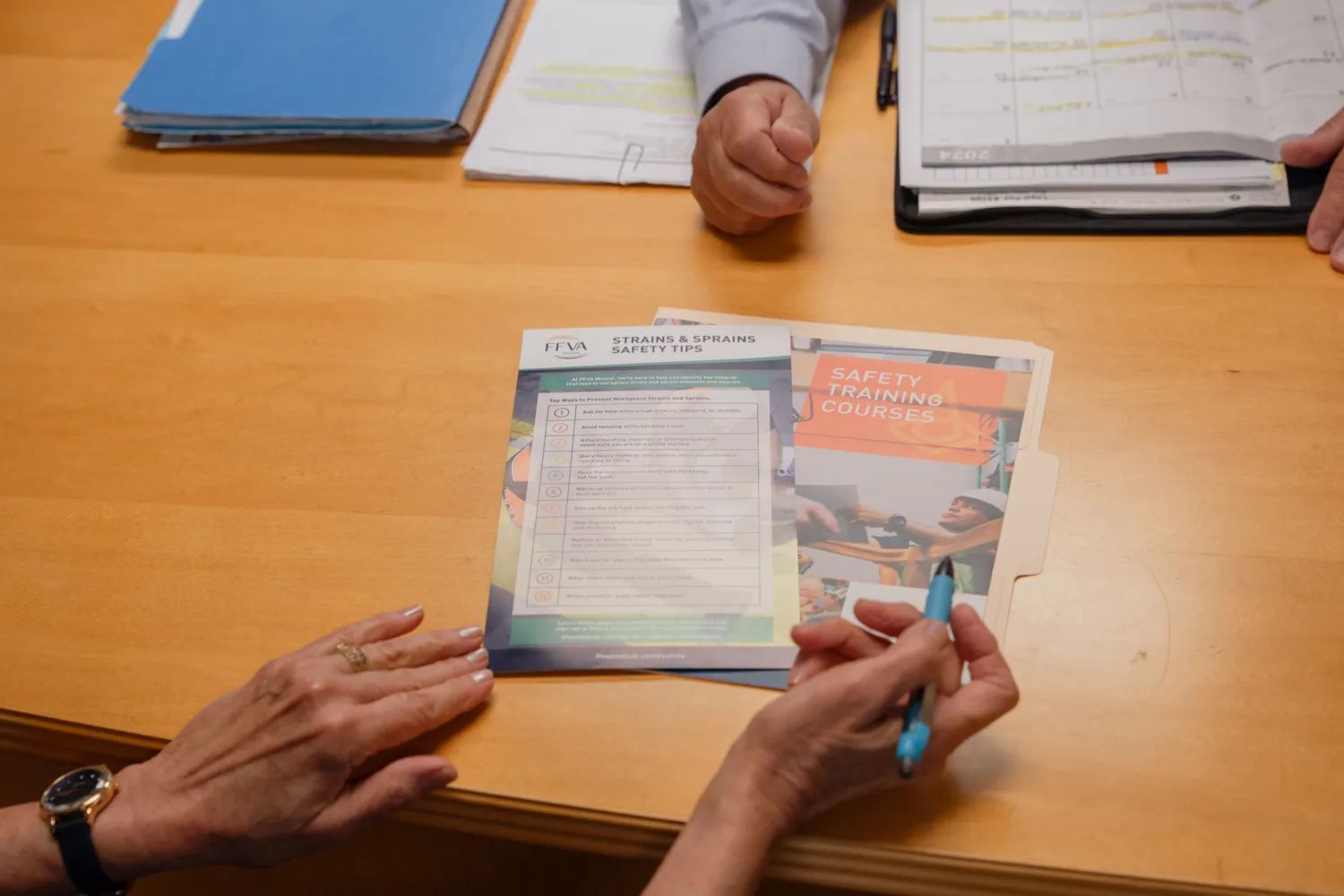

Strengthen Your Fleet Safety with FFVA Mutual

Are you looking to elevate your fleet safety program? Take a look at the FFVA Mutual employer toolkit or check out our recent post on workplace cell phone policies. Our expert safety consultants also offer a defensive driving course at no cost to policyholders.