Safety Audits 101

Workplace safety isn’t just a policy — it’s the backbone of operational success. Every year, preventable accidents cost businesses billions in fines, lost productivity and human suffering. But what if you could identify risks before they escalate?

Safety audits offer a proactive, systematic approach to uncovering gaps in compliance, safety procedures and employee practices.

These audits go beyond routine safety inspections, which focus on spotting hazards like wet floors or faulty equipment. Instead, safety audits evaluate the entire ecosystem — including policies, training, leadership and employee behavior — to ensure long-term safety performance.

In this guide, you’ll learn:

- What a safety audit entails (and how it differs from daily safety inspections).

- Why audits are critical for meeting safety regulations and protecting your team.

- How to conduct your own effective safety audit, step by step.

What Is a Safety Audit?

A safety audit is a structured, thorough evaluation of your organization’s safety practices, policies and compliance with Occupational Safety and Health Administration (OSHA) standards. Think of it as a diagnostic tool for your safety culture: It identifies weaknesses in documentation, training and day-to-day operations, providing a roadmap for improvement.

Safety Audits vs. Safety Inspections

While both are essential, they serve distinct roles:

- Safety inspections: Focus on immediate hazards (e.g., broken machinery guards, blocked exits), and are conducted frequently (daily/weekly).

- Safety audits: Assess why hazards exist. For example, an audit might reveal that inadequate training leads to improper equipment use. Conducted quarterly or annually.

Types of Safety Audits

There are a few different types of safety audits to know about:

- Compliance audits: Verify adherence to safety legislation (e.g., OSHA 1928 for agriculture).

- Program audits: Evaluate the effectiveness of written safety programs.

- Management system audits: Review leadership’s role in fostering safety initiatives.

- Process-specific audits: Target high-risk tasks like lockout/tagout procedures.

- External audits: Conducted by third-party safety auditors for unbiased insights.

Why Safety Audits Matter

Ignoring safety audits is like navigating a storm without a compass — risky, costly and avoidable.

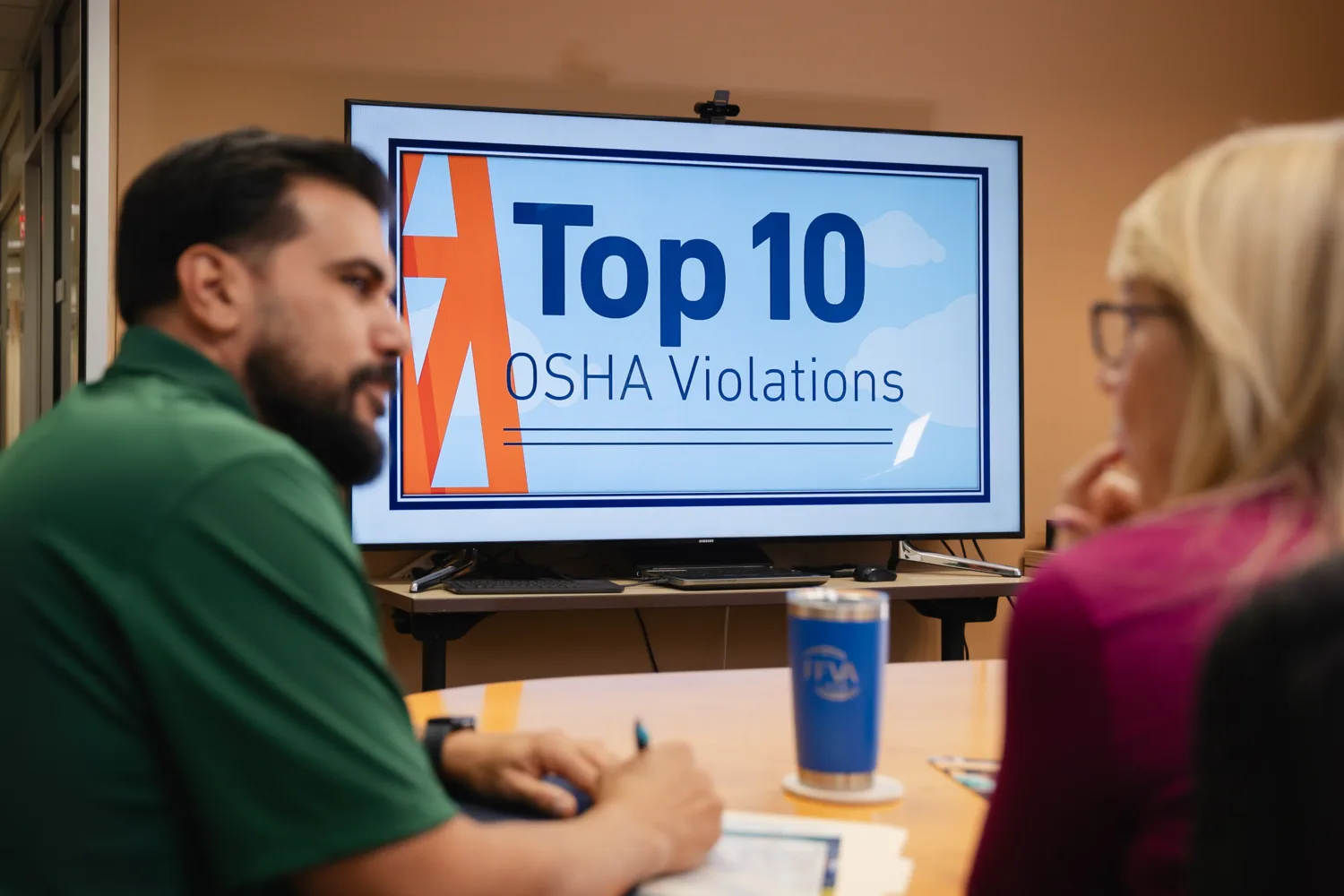

Consider these consequences of neglecting audits:

- Fines: OSHA penalties for serious violations exceed $16,500 per incident, and repeat offenders face doubled fines.

- Injuries: Workplace accidents often stem from poor safety practices, like improper equipment use or inadequate training.

- Reputational Damage: A single avoidable incident can erode trust with clients, employees and insurers.

But beyond the negatives, safety audits can also offer a few benefits.

5 Benefits of Regular Safety Audits

1. Ensure Compliance with OSHA and Safety Regulations

Audits verify adherence to standards like OSHA 1910 (general industry) or 1928 (agriculture). For instance, a compliance audit might flag missing personal protective equipment (PPE) logs, helping you avoid citations.

2. Identify Gaps in Safety Management Systems

Audits reveal systemic issues, like outdated safety policies or inconsistent training records. For example, a warehouse might discover that 10% of forklift operators lack certification — a gap they can quickly resolve with targeted safety training.

3. Reduce Workplace Accidents and Near Misses

Proactive hazard identification helps address risks before they escalate. For example, routine audits in agricultural settings might reveal issues like unguarded machinery or improper chemical storage — issues that, when corrected, significantly lower the risk of injuries.

4. Strengthen Safety Culture Through Employee Involvement

Workers who participate in audits or safety inspections become active partners in risk prevention. This collaboration fosters trust and accountability, encouraging teams to voice safety concerns more openly and consistently.

5. Improve Documentation for Safety Programs

Audits ensure written safety programs align with real-world practices. For instance, many organizations discover through audits that fall protection plans or emergency response protocols need updating to reflect current operations — leading to clearer guidelines and improved compliance.

By prioritizing regular safety audits, you’re not just checking boxes — you’re building a resilient, compliant and safer workplace.

Preparing for a Safety Audit

A successful safety audit begins long before the audit team arrives onsite. Preparation ensures the process runs smoothly, uncovers actionable insights and minimizes disruption to daily operations.

Here’s how to set the stage for an effective safety audit:

Gather Essential Documentation

Review safety policies, incident reports, training records (e.g., forklift certifications, lockout/tagout training) and written safety programs. These documents provide a baseline for evaluating compliance and identifying gaps. For example, outdated PPE logs might reveal inconsistent enforcement of safety procedures, while near-miss reports could highlight recurring hazards like slip, trip and fall risks.

Customize Your Safety Audit Checklist

Tailor your checklist to your industry’s risks. Agricultural businesses, for instance, should include checks for chemical storage compliance with hazard communication standards, machinery guarding (OSHA 1928.57) and heat stress protocols.

Communicate the Audit’s Purpose

Frame the audit as a collaborative effort to improve workplace safety, not a blame game. Share a clear message like, “Your input is vital — let’s work together to strengthen safety for everyone.” This reduces anxiety and encourages employees to share honest feedback during interviews and observations.

Schedule Strategically

Plan the audit during peak operational hours (e.g., harvest season, production shifts) to observe real-world workflows. For example, auditing a packaging facility during a midday rush can reveal risks like rushed equipment use or blocked exits that might not surface during quieter times.

Equip Your Team with Tools

Ensure the audit team has cameras, checklists and note-taking tools to document findings. For digital efficiency, use safety audit software to log hazards in real time and generate instant reports.

Following these tips will create a solid foundation for the audit process, paving the way for actionable results that protect your team and streamline compliance.

8 Steps to Conducting a Safety Audit

Now that you’re prepared, it’s time for your safety audit. Here’s how the process works:

Step 1: Define the Audit Scope and Objectives

Begin by setting clear, actionable goals for your safety audit. For example, “Evaluate PPE compliance in warehouse areas” or “Assess lockout/tagout adherence during equipment maintenance.”

Align these objectives with safety standards relevant to your industry — OSHA 1910 for general industry, 1928 for agriculture or ANSI guidelines for machinery safety. A focused scope ensures the audit remains manageable and targeted, avoiding overwhelm for your audit team.

Step 2: Assemble an Audit Team

A well-rounded audit team combines expertise from different roles: safety professionals to interpret regulations, supervisors to contextualize workflows and frontline workers to highlight day-to-day challenges.

For instance, a farm audit team might include a safety officer, equipment operator and harvest supervisor. Cross-departmental representation ensures diverse perspectives, uncovering risks a single evaluator might miss. For external audits, certified safety auditors add impartiality, particularly useful for high-stakes evaluations.

Step 3: Conduct On-Site Observations

Visit worksites during active operations to observe real-world safety practices. Document conditions with photos, checklists and notes — for example, recording unguarded machinery in a packaging facility or improper chemical storage in a barn.

Use hazard identification techniques to trace issues to their root cause. Engage employees informally: Ask a forklift operator how they perform pre-shift inspections or a fieldworker about heat stress protocols.

Step 4: Interview Employees and Managers

Structured interviews reveal gaps in training and compliance. Ask questions like:

- How often do you receive refresher safety training?

- Have you encountered obstacles when reporting safety concerns?

- What changes would make your daily tasks safer?

Ensure anonymity to encourage candid responses. For example, a poultry plant worker might disclose shortcutting sanitation steps due to time pressure — a risk needing systemic fixes, not individual blame.

Step 5: Identify Hazards and Non-Compliance Issues

Pinpoint risks using industry-specific examples. In agriculture, common findings include unguarded PTO shafts (violating OSHA 1928.57), improper pesticide labeling (failing hazard communication standards) or blocked fire exits in grain handling facilities (violating OSHA 1910.272). For construction, focus on fall protection or slip/trip hazards. Document each issue with photos, location details and relevant safety regulations.

Step 6: Analyze Data and Prioritize Risks

Compile findings into an audit report, categorizing issues by severity and likelihood using a risk matrix. For example:

- Critical: Unguarded machinery with high injury potential.

- Moderate: Frayed electrical cords in low-traffic areas.

- Low: Missing signage in storage rooms.

Prioritize corrective actions for critical risks first. Share the report with leadership to secure buy-in for urgent fixes, such as immediate equipment repairs or retraining.

Step 7: Implement Corrective Actions

Assign clear responsibilities and deadlines. For instance, require maintenance crews to install machine guards within 48 hours or schedule lockout/tagout retraining by week’s end. Update safety policies to address recurring issues — like mandating weekly PPE checks — and communicate changes through safety meetings or toolbox talks.

Step 8: Monitor Progress and Schedule Regular Audits

Conduct follow-up safety inspections within 30 days to verify compliance. Integrate audits into your management system by scheduling them quarterly or biannually. Encourage employees to participate in safety initiatives like peer-led inspections or safety moment discussions. Consider external audits annually to validate internal efforts and uncover blind spots.

Strengthen Your Workplace Safety with FFVA Mutual

Conducting regular safety audits is a proven way to protect your employees, ensure compliance and build a workplace where safety is everyone’s responsibility. But you don’t have to navigate this process alone.

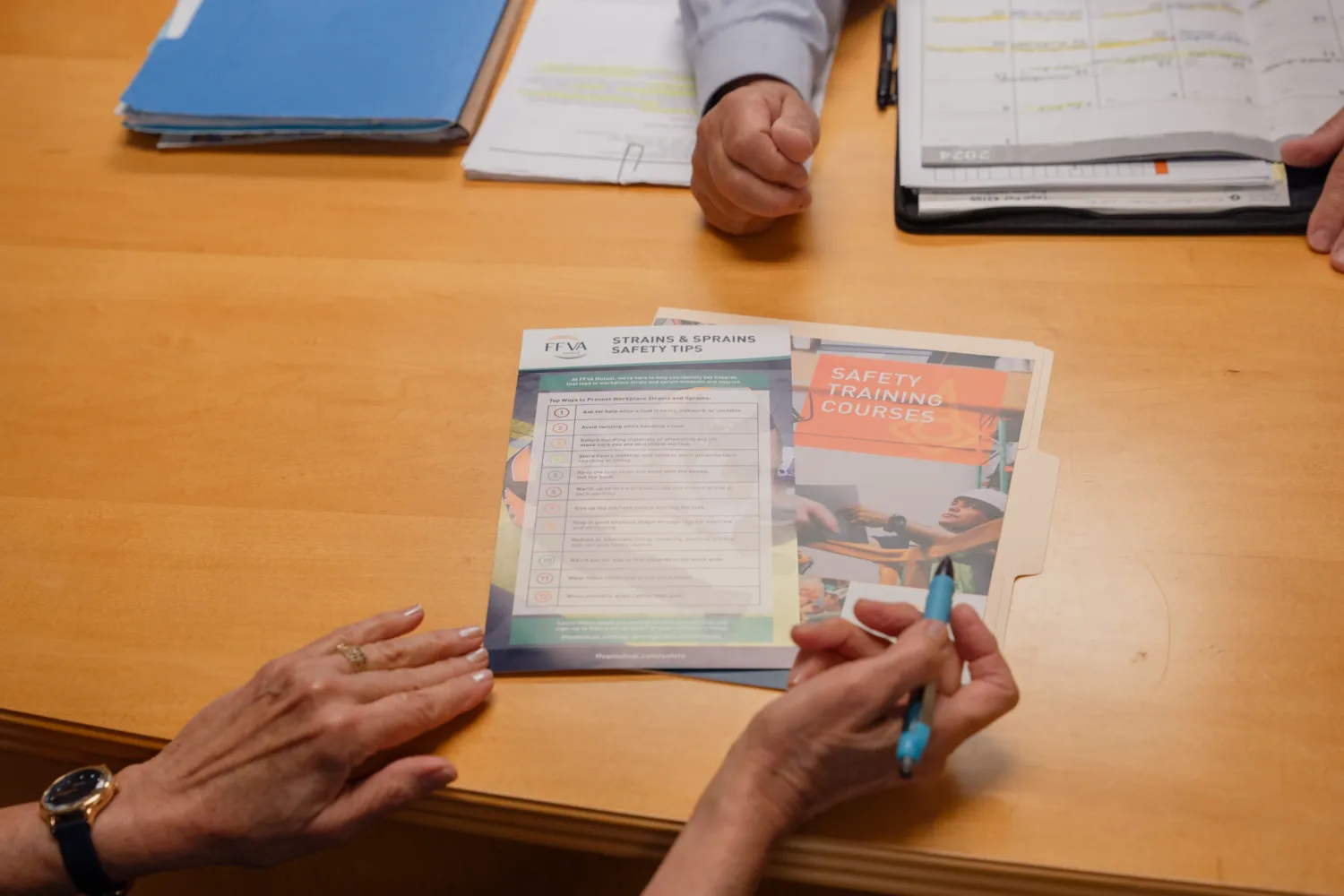

At FFVA Mutual, we’re committed to helping businesses like yours create safer workplaces through:

- Customized training programs: From OSHA compliance to hazard communication, our courses equip teams with practical skills.

- Written safety program development: Tailored plans that align with your operations and regulatory requirements.

- Safety leadership strategies: Tools to empower managers and frontline workers as safety advocates.

Ready to elevate your safety practices?

Join our free webcast, “Conducting Safety Audits & Inspections,” where industry experts will share actionable insights for conducting effective safety audits and transforming findings into lasting improvements.