Hazard Communications

Hazard communications (HazCom) play a leading role in any workplace safety program by keeping employees and business partners informed about dangerous chemical products, harmful substances and other physical hazards. According to the most recent data available from the U.S. Bureau of Labor Statistics (BLS), there were 297 chemical-related fatalities between 2011 and 2017, most of which occurred in high-risk industries. To offset the threat posed by hazardous material, the Occupational Safety and Health Administration (OSHA) maintains detailed standards for hazard communication programs that certain employers must follow. Understanding what’s required under OSHA’s guidelines is not only crucial for avoiding costly penalties, but it’s also considered a best practice for employers who deal with chemicals in the workplace.

What is Hazard Communication?

Hazard communication is the set of processes and procedures organizations use to protect workers from hazardous substances that pose a risk to their health and safety. These programs are particularly important for workplaces that store, use or process chemical products as their workforces are more often exposed to hazardous chemicals. The OSHA Hazard Communication Standard includes requirements for labels and safety data sheets, as well as employee communication such as information and training. These protective measures have been shown to improve occupational safety and reduce the frequency of on-the-job injuries and illnesses.

As noted by OSHA, all employers with hazardous chemicals in their workplaces must “prepare and implement a written hazard communication program.” This involves obtaining and maintaining material safety data sheets (SDS), which contain detailed information on the potential health consequences of exposure to each substance, and the requirements for safely handling and storing them. Employers must also carefully label hazardous chemicals whether they’re being shipped, stored or used by any on-site worker.

According to research from the Centers for Disease Control and Prevention (CDC), the five most common substances that cause “chemical exposure injuries” on job sites include:

- Ammonia

- Carbon monoxide

- Chlorine

- Hydrochloric acid

- Sulfuric acid

While OSHA’s hazard communication standards are quite comprehensive, there are some substances that are exempt (under 29 CFR 1910.1200(b)(6)). These exemptions include tobacco products, certain hazardous waste, cosmetics and other materials that don’t pose an immediate threat to your employees. Keep in mind, OSHA is continuously updating its standards to be more relevant and reliable, so it’s important to stay on the lookout for new hazard warnings and communication rules.

Who is Responsible for Hazard Communications?

Ultimately, the employer is responsible for providing a safe working environment. This includes complying with OSHA’s hazard communication standard (HCS), 29 CFR 1910.1200 (h) and ensuring that employees are adequately trained in hazardous materials handling. That’s because employers are the ones who know their workplaces and the hazards associated with them. They’re also likely to have access to resources that can help them comply, such as safety data sheets (SDSs) and training materials.

Even for temporary workers and contractors, the host employer is responsible for ensuring that they receive the appropriate training and hazard information. A best practice is to conduct an assessment prior to initiating work on any project and designate a work area supervisor to oversee operations — including any safety precautions and evacuation procedures.

Supervisors should have extensive training in handling hazardous material, first aid, and immediate access to a radio or telephone. That said, all employees should be aware of the hazards and should know what to do in case of an emergency.

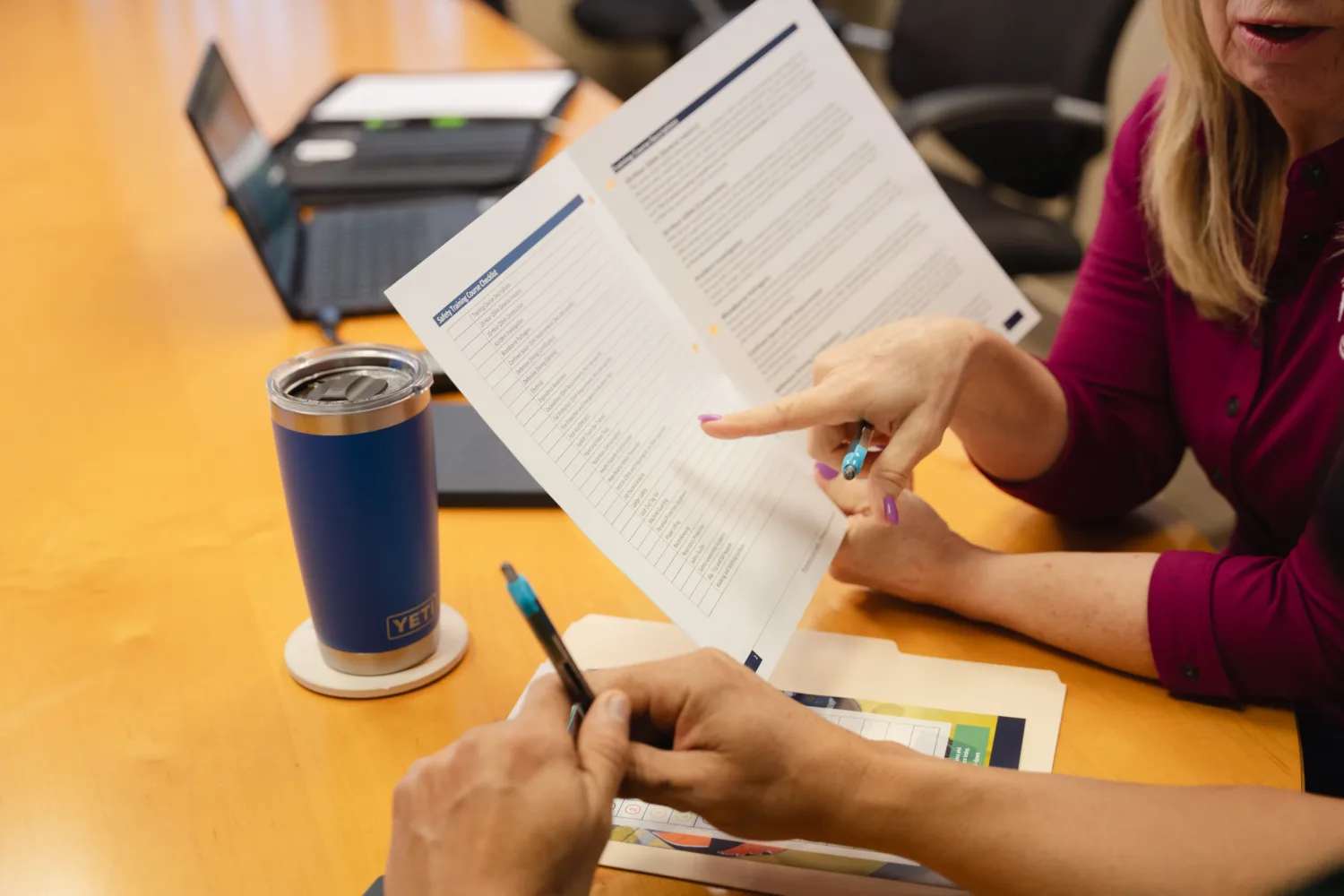

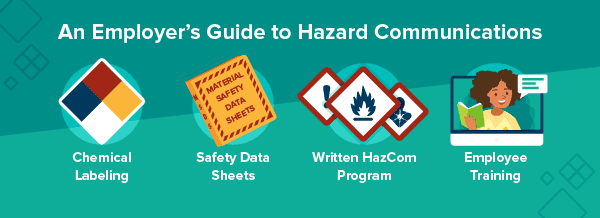

4 Key Elements of an Effective HazCom Program

If your company uses, produces or imports hazardous materials, there’s a good chance you already have a hazard communication program in place. Of course, like with most other workplace safety issues, there’s always room for improvement. Under OSHA’s Hazard Communications Standards, organizations must uphold four main requirements:

1. Ensure Proper Chemical Labeling

Employers are responsible for ensuring that all containers housing hazardous chemicals and substances are properly labeled. These labels must be legible, written in English and prominently displayed so employees can quickly identify harmful materials.

In terms of the required information, OSHA outlines six characteristics that all HazCom labels must include:

- Product identifiers

- Signal words

- Hazard statements

- Precautionary statements

- Pictograms

- Contact information for the “responsible party” (usually the manufacturer or importer)

Back in March 2012, OSHA made sweeping changes to the Hazard Communication Standards to bring them more in line with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) used by the European Union. One of the most impactful changes has to do with the pictograms used on hazardous chemical labels. Under the new guidelines, chemical manufacturers must incorporate the nine GHS pictograms into their HazCom labeling strategies, as these are more widely recognizable than previous versions.

2. Update and Share Safety Data Sheets

A material safety data sheet (SDS) provides detailed information about the hazardous substances used in your workplaces, including the properties of each substance, any related physical and/or health hazard, key protective measures and more. In most cases, safety data sheets are created by chemical manufacturers and importers before being sent out to other users. Beyond keeping employees informed about potential risks, employers can leverage these documents to develop more active workplace safety policies and training programs around the proper handling of chemical hazards. Safety data sheets are required for every hazardous chemical stored or used at every facility.

OSHA’s updates also made a few important changes to the information that must appear on safety data sheets. The new HazCom guidelines include a 16-section format that every safety data sheet must follow, which is a bit more comprehensive than the original standard. Under the new rules, safety data sheets should contain the following sections:

- Substance identification

- Hazard(s) identification

- Composition and/or information on ingredients

- First-aid measures

- Firefighting measures

- Accidental release measures

- Handling and storage guidelines

- Exposure controls and personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information

- Disposal considerations

- Transportation guidelines

- Regulatory information

- Other relevant information

In terms of employer responsibilities, you must ensure that all safety data sheets are up to date and readily accessible to all employees. To avoid possible complications in case of an unexpected outage, you should make safety data sheets available in both print and digital formats. OSHA also recommends assigning a dedicated HazCom advisor who will be responsible for maintaining your safety data sheets and working with chemical manufacturers when new information is released. For additional information, watch this brief SDS short talk webcast.

3. Develop a Written Hazard Communication Program

Another important facet of OSHA’s Hazard Communication Standard involves creating and maintaining a written hazard communication program. These documents should explain, in detail, how your worksites will implement OSHA’s HazCom standards, which will help make your program more systematic and coordinated. When these HazCom blueprints, you should make sure the following information is included:

- A complete inventory of all hazardous materials

- Specific procedures for labeling hazardous chemicals

- Guidelines for managing safety data sheets

- Required employee training for HazCom

- Detailed action plans for chemical spills, fires and or any other physical hazards

While these requirements are non-negotiable for most employers with chemicals in the workplace, there are some exceptions. For example, research laboratories do not need to create a written hazard communication program. Additionally, worksites that only handle chemicals in sealed containers are also exempt from OSHA’s written program requirements.

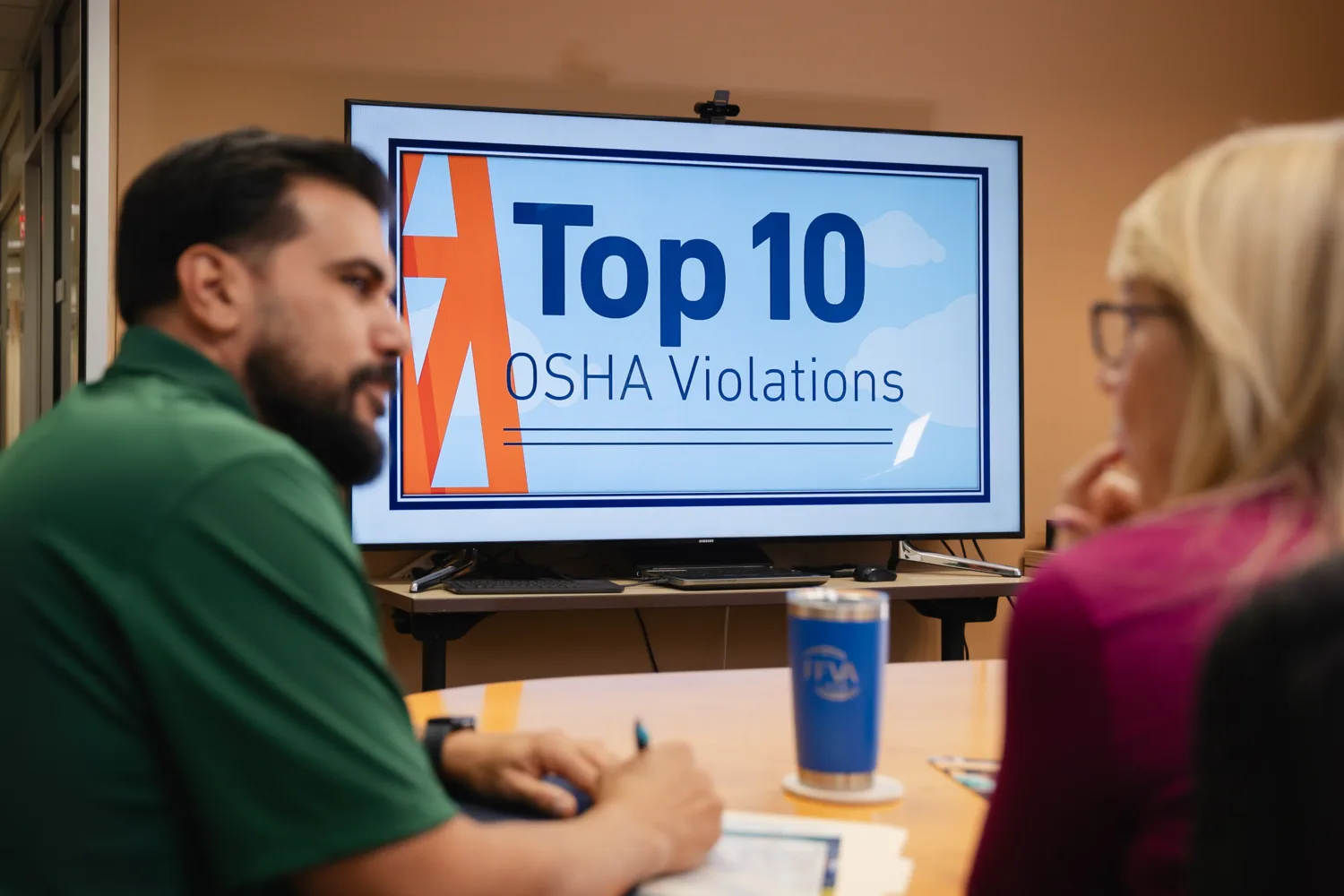

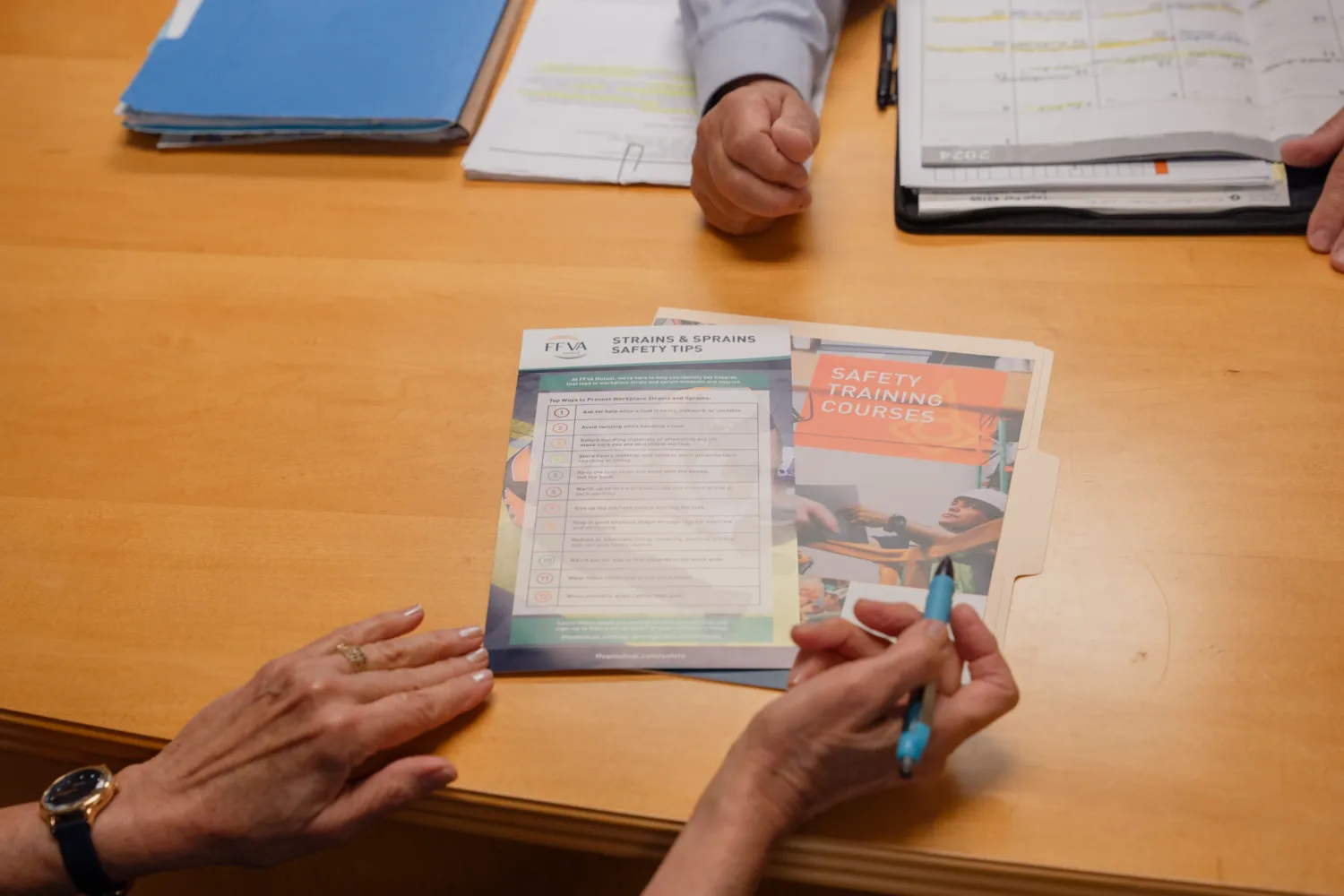

4. Training Employees on Chemical Hazards

The final (and perhaps most important) element of OSHA’s Hazard Communication Standard involves employee training requirements. Any worker who is exposed to a hazardous chemical must be trained on the proper handling and use of hazardous substances. They must also be aware of available protective measures that help reduce the risk of spills, fires, aerial dispersal, and other physical hazards. Since job site conditions change over time, you should regularly retrain your employees when new workers are onboarded, when new hazardous substances are introduced, and after an on-the-job accident has occurred.

Understanding workplace hazards is key to keeping employees safe. From chemical exposure to physical dangers, recognizing potential risks is the first step in prevention. Learn more about common safety hazards in the workplace in our blog: Understanding Safety Hazards in the Workplace.

At FFVA Mutual, we believe that employee health and safety is a continuous process. Our safety consultants offer free onsite training for policyholders to help you develop an effective written hazard communication program, maintain accurate safety data sheets, and stay compliant with OSHA’s Hazard Communication Standards.

To learn more, watch our HazCom webcast or reach out to a Solutionist today.