Everything You Need To Know To Keep Your Workers Safe

Let’s talk about something that’s both essential and, sadly, often overlooked – electrical safety. But what is electrical safety, really? Simply put, it’s the set of precautions and protocols designed to minimize the risks associated with electrical equipment, circuits and power lines in a work setting.

Sure, we’ve come a long way … Statistics from the National Fire Protection Association (NFPA) tell us electrical injuries requiring time away from work have been nearly halved since the 1990s. But here’s what’s concerning – 150 workers still die from exposure to electrical hazards every year, according to the Electrical Safety Foundation International. And let’s be clear: Even one is one too many.

So, what can you do? Awareness and vigilance are your best friends. Combine that with rigorous electrical safety training and unwavering adherence to a set of protocols, and you’re on the right track. Keep reading to learn more.

Understanding Electrical Safety

The workplace is a unique beast when it comes to potential electrical hazards. Unlike the home, where concerns can be more manageable, a work environment often includes a diverse range of electrical equipment, overhead power lines and a more complex electrical system.

Think about it: You’ve got machinery and electrical tools running with power cords snaking across the floor and let’s not forget about the circuit breaker that might or might not be older than your favorite classic rock hits. All these elements contribute to a greater risk of potential electrical hazards which is why the workplace requires another level of expertise. Here’s where compliance with regulations comes in.

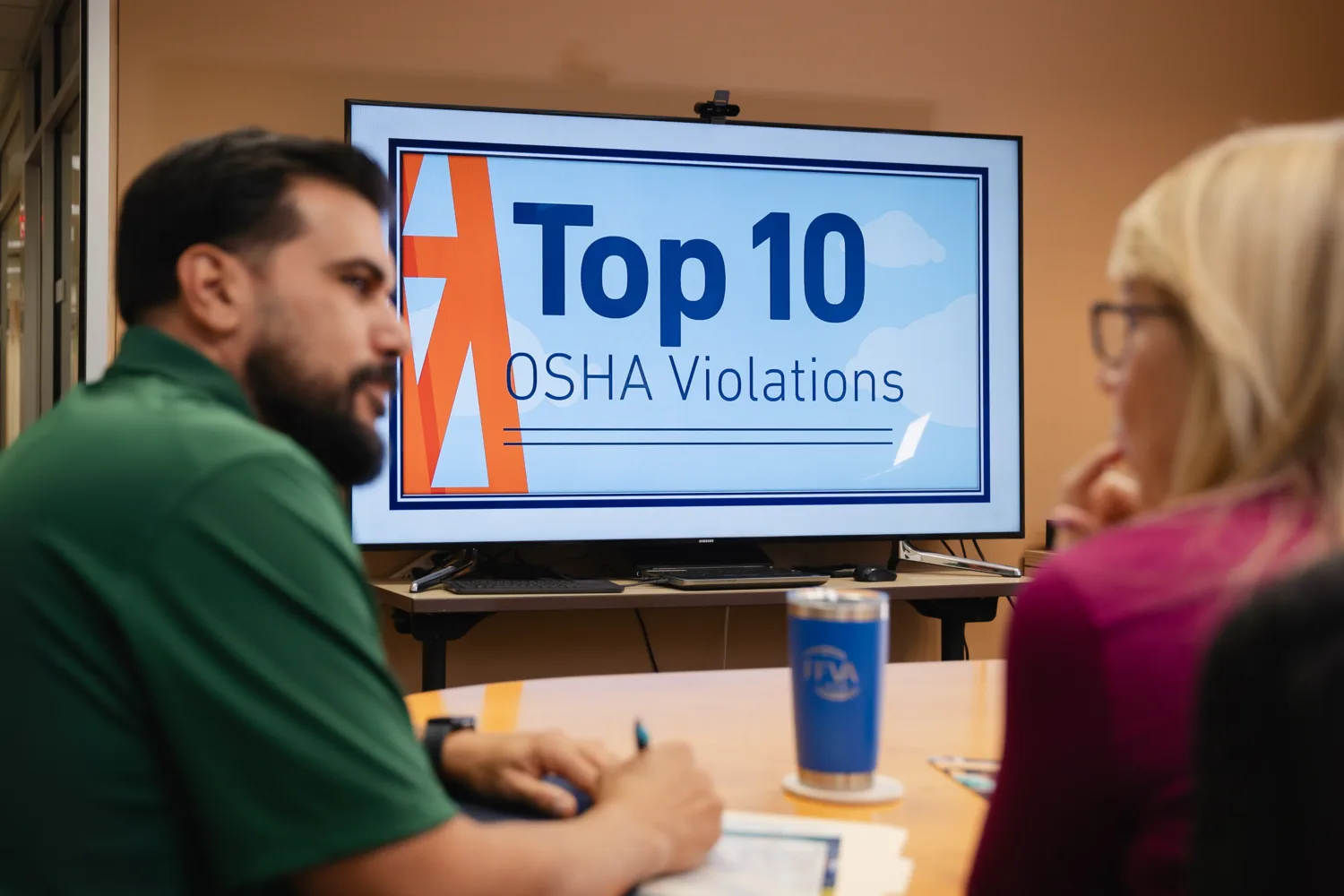

OSHA 1910 Subpart S for general industry covers everything from electrical installation requirements to the kind of personal protective equipment (PPE) employees should be wearing. Moreover, the National Electrical Code (NEC) — which has been adopted in all 50 states — also sets the baseline for safe electrical design and installation. Both of these resources should be your blueprint and your reference manual as you work to create an effective electrical safety program. And don’t forget to review and update it annually or each time you introduce new appliances, tools or processes.

Essential Tips for Electrical Workplace Safety

Now that we’ve gone through the rules and regulations, let’s pivot to something a bit more hands-on — concrete tips for electrifying your safety game at work.

1. Spot and Secure Exposed Wiring

Although an electrical wire may look benign, exposed wiring is an accident waiting to happen. Don’t procrastinate when it comes to this and let your maintenance team know as soon as possible. Not only do exposed wires pose an electric shock risk, but they can also be a fire hazard. And by the way, if you find it on an extension, replace the electrical cord entirely — no duct tape solutions here.

2. Deal With Bare Wiring Immediately

This sounds similar to exposed wiring, but there’s a crucial difference between the two. While exposed wiring remains insulated, bare wiring is completely stripped off. This turns it into an immediate shock, fire and electrical hazard. It should never be approached — instruct all employees to report any instances of bare wiring straight away so they can be properly and safely addressed by professionals.

3. Watch Out for Water

Water’s love affair with electricity is a dangerous liaison. A wet environment ramps up the stakes, transforming minor electrical hazards into potential disasters. If you spot standing water near electrical components or an electrical outlet, it’s crucial to resolve it immediately. Your safety protocols should include methods to remove the water safely and quickly.

4. Be Smart With Extension Cords

An extension cord isn’t just a “longer wire.” A bad one can wreak havoc. Before you plug in, make sure it’s not frayed or damaged. It should also have a ground prong — no exceptions. Remember, the cord should be robust enough to handle the electrical load you’re putting on it. Using an under-rated extension cord can lead to overheating and, you guessed it, electrical fires.

5. Use a Ground-Fault Circuit Interrupter (GFCIs)

When it comes to electrical safety near water, GFCIs are your first line of defense. Building codes often require them, but sometimes they’re not present. In that case, portable GFCIs can easily integrate into your extension cord setup in outdoor or high-moisture environments. If you’re dealing with standing water, remove it to cut down the risk and make sure your portable GFCI is in play.

6. Handle Hand-Held Power Tools With Care

In the industrial environment, hand-held power tools are everyday essentials, yet they frequently get sidelined in safety discussions. Make no mistake: Each tool should meet critical grounding requirements, either through double insulation or a grounding prong. Eliminating the ground prong for the sake of convenience compromises not just the machinery, but the entire safety landscape of your operation.

7. Keep Switches, Plugs and Junction Boxes in Check

Little things can lead to big problems. Make sure switches, plugs and junction boxes are in top shape. See signs of wear and tear? Replace them, and always opt for professional repair over DIY when it comes to any electrical system.

8. Master Your Emergency Response Mechanisms

In any workplace setting, having a well-defined electrical emergency response plan is a necessity that could save lives and mitigate damage. Make sure your team is versed in the locations of fire extinguishers and trained in administering first aid for an electrical burn. Treat this information as integral to your organization’s risk management strategy.

There’s Been an Electrical Incident — What To Do

So, the unthinkable has happened: there’s been an electrical incident. What now? The initial response needs to be rapid and precise. Activate emergency protocols, administer first aid if required and secure the area. Once the immediate threat is neutralized, the real work begins: dissecting what went wrong. A thorough incident investigation should be launched, both to meet compliance requirements and to discover the root cause of the occurrence.

Communication is crucial here. Transparency with your team can foster a culture of safety and accountability. Provide psychological and medical support to those affected; remember, the aftermath can be as traumatic as the incident itself. As for preventing future incidents, use your newfound knowledge as a catalyst for change. Review and update procedures and protocols, and ensure your staff are re-trained to meet these new electrical safety standards.

It’s equally important to document the injury for workers’ compensation. A well-documented incident can expedite the claims process, ensuring your team gets the medical attention and support they require. Moreover, as you’re preparing your team’s return to a safer work environment, consider integrating a return-to-work program — these are beneficial to both employee morale and your bottom line.

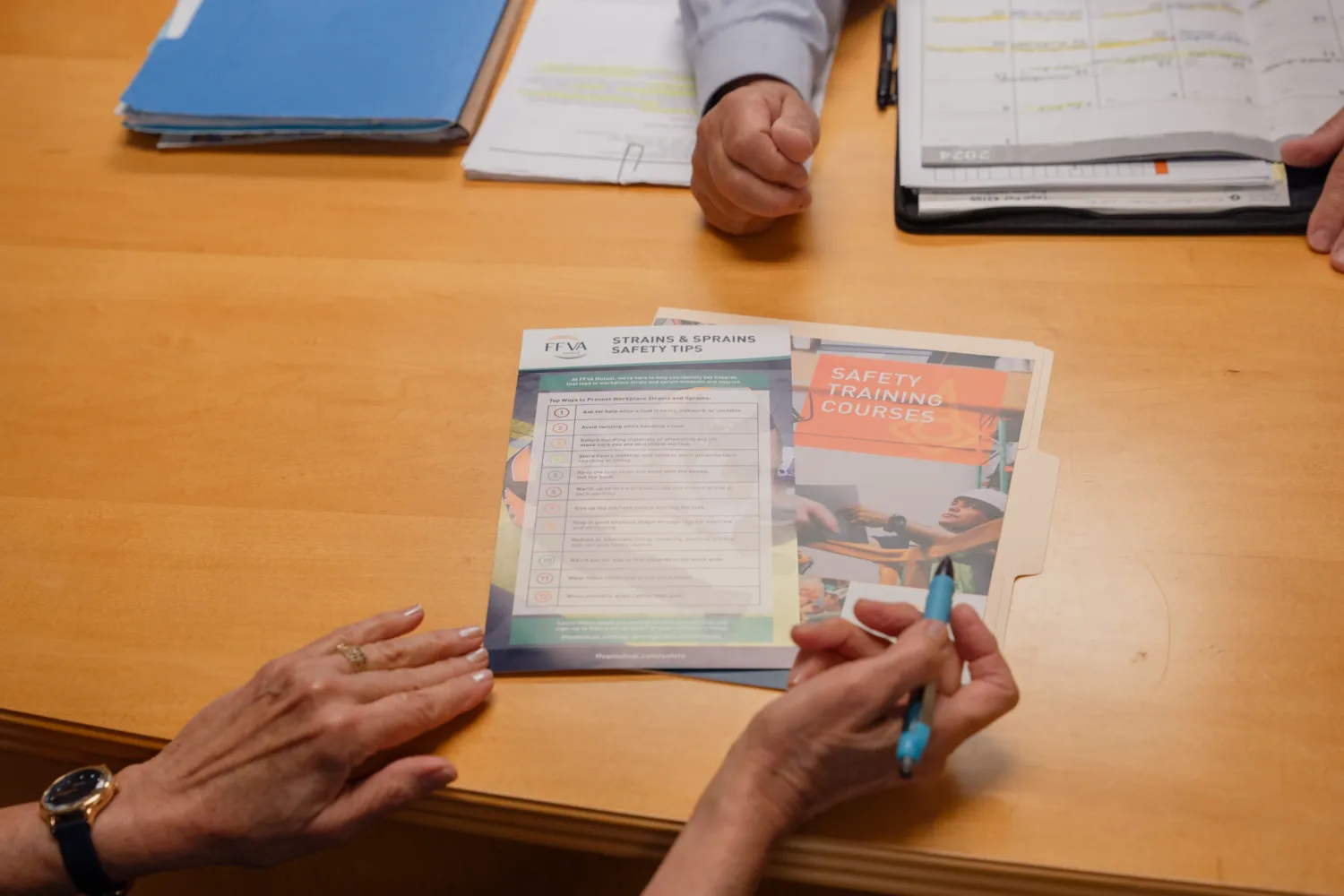

Empower Your Workforce With Knowledge

Wrapping up, empowerment through knowledge is the ‘spark’ that ignites a culture of safety. And that’s exactly what we’re offering here at FFVA Mutual — from up-to-the-minute safety tips and resources to expert support for your most pressing questions. Flip the switch today and illuminate your path to a safer, more compliant work environment.