Workplace Safety Training: Why Your Company Needs It

Workplace safety training for employees is essential for every company. Through general workplace safety training programs, company management can ensure a safe work environment. It prepares the employees for any hazardous situation and helps them stay as safe and healthy as possible.

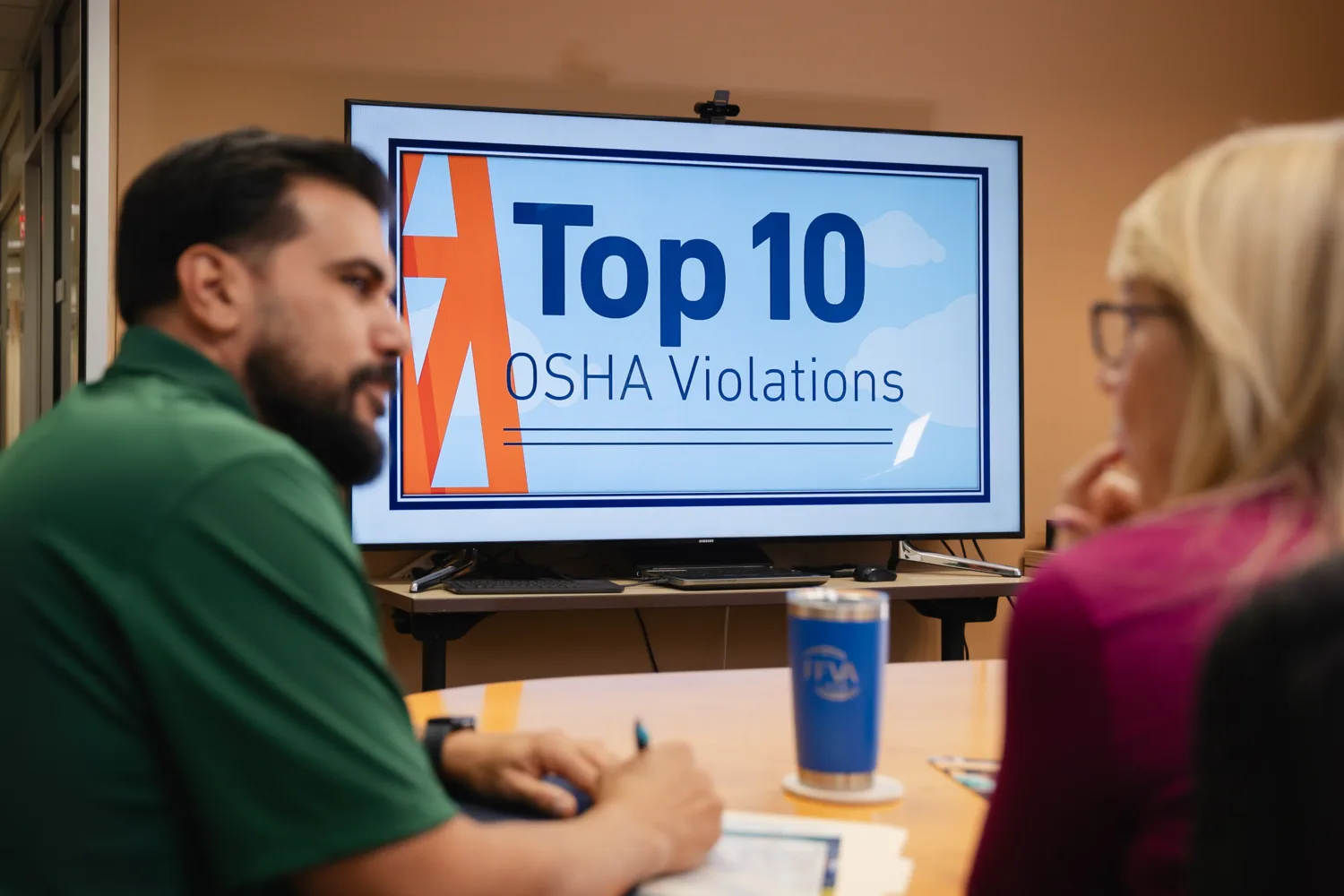

Many companies are required to include specific workplace safety training for employees because standards from the Occupational Safety and Health Administration (OSHA) include very strict safety requirements for their industry. However, even if OSHA doesn’t explicitly require you to include employee safety training, there are still numerous reasons to do so.

In this article, we will talk about workplace safety training, why every company needs it, and cover the best practices for running a program of your own.

What is OSHA Workplace Safety Training?

OSHA standards for various industries contain specific requirements when it comes to employee safety training. Companies in construction, maritime, agriculture, and general industries are required to conduct workplace safety training to make sure their employees are capable of keeping themselves and others safe.

Many workers need an official Department of Labor (DOL) card to stay compliant with OSHA standards, and the only way to get a DOL card is by completing an OSHA outreach training program. It consists of 10-hour and 30-hour courses that provide basic or advanced knowledge and training about workplace safety.

However, many workers don’t need an official DOL card, and all they need for staying compliant with OSHA standards is a proper training program that teaches them how to stay safe while working. Depending on the specific responsibilities of an employee, employers must provide them with training related to their operations on the worksite.

Why Offer do Safety Training?

Staying compliant with safety standards isn’t just about avoiding penalties. Every employee has the right to and should work in a healthy and safe environment. Good employee safety training handouts are of tremendous value for your employees and your company.

Through education and training, you provide your managers and workers with vital information and skills that help them do their jobs safely and be more productive. Another crucial role of a workplace safety education program is to provide employees with a thorough understanding of the program itself and enable them to contribute to its development.

Specialized safety training for employees is vital for your workers and your company, especially when their work involves hazards. Awareness and understanding of workplace hazards, as well as knowing how to spot and control them, will help keep everyone safe.

10 Safety Meeting Topics Every Workplace Should Address

While OSHA mandates industry-specific training, these 10 essential safety meeting topics form the backbone of any proactive safety program, especially in high-risk sectors like agriculture, construction and manufacturing:

Slips, Trips and Falls

Slips, trips and falls are among the most common causes of workplace injuries, particularly in environments like warehouses, farms or construction sites. Training should emphasize identifying workplace hazards such as wet floors, cluttered walkways or uneven surfaces. Reinforce safety protocols like wearing slip-resistant footwear, marking spills immediately and maintaining clear pathways. For outdoor workers, address risks like muddy fields or unstable terrain.

Fire Safety and Prevention

Fire safety training goes beyond evacuation drills. Teach employees the PASS technique (Pull, Aim, Squeeze, Sweep) for fire extinguisher use and how to identify electrical safety risks like frayed cords or overloaded circuits. For instance, in agricultural settings, focus on safely storing flammable materials such as hay, pesticides or fuel. Regularly review fire prevention strategies, such as proper disposal of oily rags or maintaining distance between heat sources and combustible items.

Emergency Preparedness

Tailor emergency plans to your workplace’s unique risks. For Southeastern businesses, this might mean hurricane preparedness drills, while Midwest warehouses may prioritize tornado response. Conduct safety toolbox talks to review evacuation routes, assembly points and communication chains. Include training on first-aid kits, emergency shut-off procedures and crisis leadership roles to ensure everyone knows their responsibilities during an incident.

Hot and Cold Weather Safety

Extreme temperatures pose significant risks to workers, particularly in outdoor industries like farming or construction. For heat safety, train teams to recognize signs of heat exhaustion (e.g., dizziness, rapid pulse) and enforce hydration breaks, shaded rest areas and lightweight personal protective equipment (PPE). In colder climates, focus on frostbite prevention with layered clothing, insulated gloves and wind-resistant gear. Adjust work schedules to avoid peak temperature extremes whenever possible.

Hydration and Fatigue Management

Dehydration and fatigue directly impact safety performance, leading to slower reaction times and poor decision-making. Provide electrolyte supplements during heatwaves and educate employees on recognizing symptoms like dark urine or persistent tiredness. For night shifts or long-haul drivers, implement rest-break schedules and discourage overtime that leads to burnout. Simple safety measures like accessible water stations can prevent costly accidents.

Company Health Resources

A holistic approach to workplace safety includes mental and physical health. Offer resources like onsite clinics, telehealth options or partnerships with local healthcare providers. For example, farming crews exposed to pesticides might benefit from regular health screenings. Promote wellness programs that address nutrition, smoking cessation or stress management, tying these initiatives to broader safety culture goals.

Mental Health Awareness

Stress and anxiety contribute to workplace accidents by impairing focus and increasing errors. Train managers to recognize signs of burnout, such as irritability or decreased productivity and provide access to counseling services. Host workshops on mindfulness or time management, and normalize conversations about mental health during safety meetings. For high-pressure roles like equipment operators, emphasize the link between mental well-being and safety outcomes.

Workplace Violence Prevention

Workplace violence training should teach de-escalation techniques and how to identify warning signs, such as aggressive body language or verbal threats. Use role-playing scenarios to practice responses to conflicts and establish clear reporting channels for safety concerns. In retail or healthcare settings, you might train employees on how to deal with agitated customers or patients, while agricultural operations might focus on securing remote worksites.

Distracted Driving

For employees who operate vehicles — whether delivery trucks, tractors or forklifts — distracted driving training is critical. Enforce strict “no phone” policies, mandate pre-trip inspections and share statistics on distracted driving: it claimed over 3,300 lives in 2022 alone. Include modules on defensive driving, weather-related hazards and proper seatbelt use to reduce motor vehicle safety incidents.

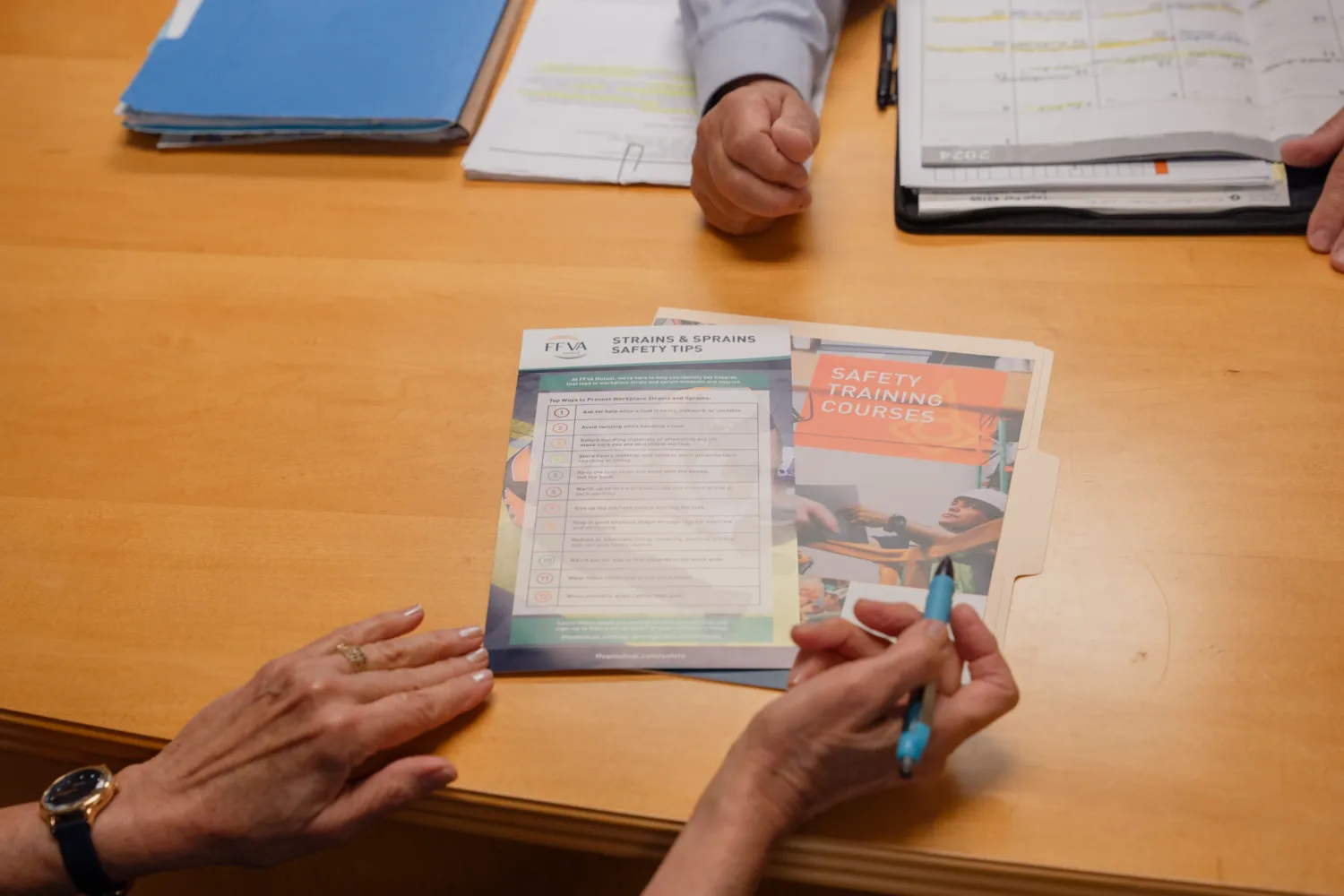

Ergonomic Safety

Repetitive motions and poor posture lead to musculoskeletal disorders, especially in labor-intensive roles. Train teams on proper lifting techniques (bend knees, keep loads close to the body) and adjust workstations to reduce strain. For office workers, emphasize monitor height, chair support and frequent stretching. Other industries may use ergonomic tools like padded gloves, hard hats, respirators and other equipment to minimize long-term injuries.

By integrating these topics into your safety training programs, you create a culture where employees actively mitigate risks and prioritize well-being. For industries where hazards range from heavy machinery to extreme weather, this proactive approach is not just compliance — it’s a lifeline.

How to Conduct Training

There are many ways to start an employee safety training program outside of a classroom setting. Worksite demonstration, on-the-job training, peer-to-peer training, safety committees, and online training can be remarkably effective in promoting safe work practices.

Industrial safety training consists of several important steps:

- Provide a program awareness training after you choose a specific safety program. This way, you can include all of your employees in program development.

- Train everyone on their specific roles in the program. From managers to supervisors and workers, everyone should know what to do in a hazardous situation.

- Train workers to identify hazards and train them on how to eliminate danger before a larger-scale incident occurs.

Program Examples

OSHA safety training requirements aren’t the same for every industry. They aren’t even the same for every state. For example, in Florida, Miami-Dade County, all construction employees are required to take OSHA-authorized training prior to employment on any public or private contract that is valued over one million dollars.

Depending on the industry and the specific nature of the employer’s everyday working routine, there are different training programs available. OSHA includes construction, repair and alteration, but also painting and decorating among jobs that require Construction OSHA training. When it comes to General Industry training, it’s required from any industry that doesn’t fall under construction, agriculture, or maritime. This includes industries such as manufacturing, health care, distribution and retail, warehousing, and more.

FFVA Mutual and Safety Training

OSHA continues to update the rules for safe workplace maintenance, and businesses need to make adjustments to their safety policies to stay compliant. Penalties for serious workplace safety and health violations are very high, which gives employers plenty of reasons to continue with improvements.

FFVA Mutual is a leading workers’ compensation insurance carrier licensed in 10 southeastern states. Workplace safety is of utmost priority, which is why we offer in-person and online training events for our policyholders— including OSHA 10-hour training at no cost at all for our agency partners and policyholders. Our personalized programs will help your company remain fully compliant with the newest OSHA standards and improve workplace safety. Contact us today to learn more about our training programs.